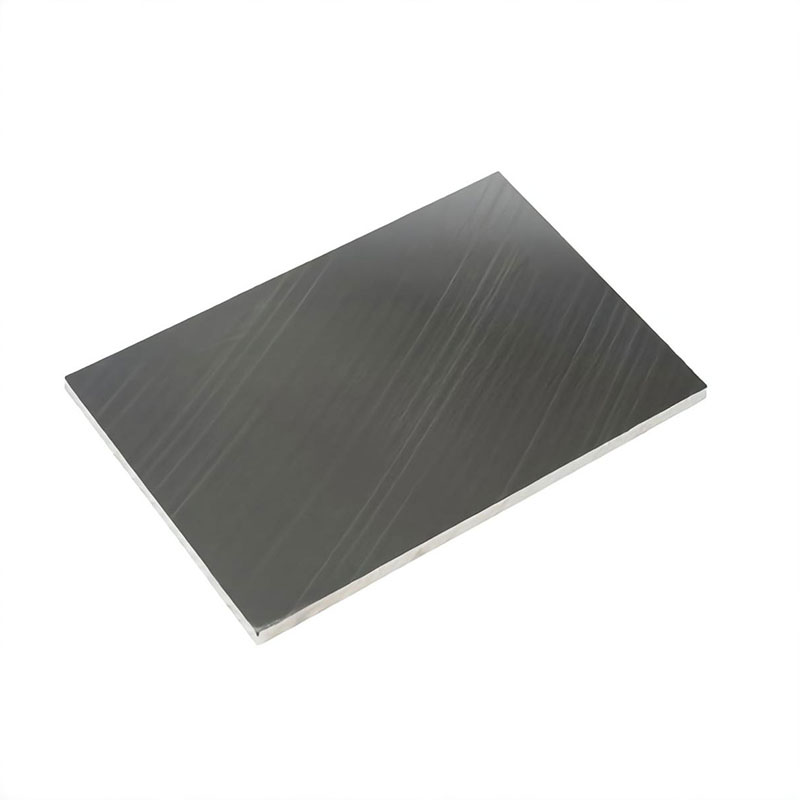

China Manufacture Supplier 1050 Aluminum Plate

Product Introduction

1050 aluminum sheet belongs to commercially pure wrought family with a purity of 99.5% Aluminium. Except Al, 0.4% of Fe is added to 1050 aluminium sheet, thus, it has high electrical conductivity. 1000 series aluminium group offers the best correction resistance compared to any alloy group, so does the 1050 aluminum sheet.

Aluminum alloy 1050 is a popular grade of aluminium for general sheet metal work where moderate strength is required.Aluminium alloy 1050 is known for its excellent corrosion resistance, high ductility and highly reflective finish.

Features

Aluminum alloys are known for their strong corrosion resistance characteristics, and the 1xxx alloy group offers the best corrosion resistance of any alloy group. 1050 aluminum is a popular alloy for general sheet metal work where moderate strength is required. Hydro typically produces extrusion in the 6000 series of alloys. This alloy is typically used in applications requiring maximum ductility and moderate strength.

1xxx series alloys display excellent forming characteristics, which permits them to be easily impacted, cold drawn, deep drawn and bent into various configurations. However, pure aluminum has only fair machinability due to the softness of the alloy.

Its properties include:

commercially pure aluminum

non heat-treatable

soft and ductile

excellent cold workabilit

excellent corrosion resistance

easily welded by MIG or TIG processes

excellent brazability and solderabilit

well-suited to chemical and electrolytic brightening

very good anodizing qualities

has a highly reflective finish

1050 aluminum sheet are widely used in general industry, scientific experiment, chemical industry and other territories. The specific application is as follows:

daily necessities, lighting fixture, lamps and lanterns, extruded coil of food;

scutcheon, nameplates, decorations;

chemical industrial container, chemical and brewing industry, cooling fin, electronics;

baffle-board,stamping parts, etc.

Specifications

|

Standard Size |

|

|

Aluminum Foil |

Thickness 0.0045mm--0.2mm Width 10mm-500mm The length supports customization |

|

Aluminum Coil |

width 1000mm/1250mm/1500mm/2500mm The length can be customized |

|

Aluminum Plate |

1000mm*2000mm/1250mm*2500mm/1500mm*3000mm/2000mm*6000mm |

|

Aluminum Strip |

Thickness 0.2mm-4mm, Width 10mm-1000mm, The length supports customization |

|

Conventional Standard Thickness |

0.2mm 0.3mm 0.4mm 0.5mm 0.6mm 0.8mm 1.0mm 1.2mm 1.5mm 2.0mm 2.5mm 3.0mm 4.0mm 5.0mm 6.0mm 8.0mm 10mm 12mm 15mm 20mm 25mm 30mm 35mm 40mm 45mm 50mm 55mm 60mm 65mm 70mm 75mm 80mm 85mm 90mm 95mm 100mm 105mm 110mm 115mm 120mm 125mm 130mm 135mm 140mm 145mm 150mm 155mm 160mm 165mm 170mm 175mm 180mm 185mm 190mm 195mm 200mm |

| Hardness H0 H12 H14 H18 H22 H24 H26 H32 H111 H114 T4 T6 Other hardness can be customized | |

| It can be used for color drawing, embossing, cutting, pattern, strip and other processing | |

|

The above are the standard common sizes of coil, and customization is supported |

|

|

Material Table |

Product Use |

|

|

1000 series |

1050 | Food, chemical and extrusion coils, various hoses, fireworks powder |

| 1060 | Chemical equipment is its typical use | |

| 1100 | Chemical products, food industry installations and storage containers, weldments, heat exchangers, printed boards, nameplates and reflective appliances | |

|

2000 series |

2024 | Aircraft structures, rivets, missile components, truck hubs, propeller components and other structural components |

| 2A12 | Aircraft skin, spacer frame, wing rib, wing beam, rivet, etc., and structural parts of buildings and transportation vehicles | |

| 2A14 | Free forging and die forging with complex shape | |

|

3000 series |

3003 | Kitchen utensils, food and chemical products, storage equipment, storage tanks for transporting liquid products, and various pressure vessels and pipelines |

| 3004 | Chemical product production and storage devices, plate processing parts, building processing parts, building tools and various lamp parts | |

| 3105 | Room partition, baffle, movable room board, eaves gutter and downpipe, sheet forming parts, bottle caps, corks, etc | |

|

4000 series |

4032 | Piston, cylinder head |

| 4043 | Building distribution frame | |

| 4343 | The products are widely used in automobiles, water tanks, radiators, etc. | |

|

5000 series |

5052 | Aircraft fuel tank, oil pipe, traffic vehicle and ship sheet metal parts, instruments, street lamp supports and rivets, hardware products, etc |

| 5083 | Plate weldments of ships, automobiles and aircraft; Pressure vessel, refrigeration device, TV Tower, drilling equipment, transportation equipment | |

| 5754 | Storage tanks, pressure vessels, ship materials | |

|

6000 series |

6005 | Ladder, TV antenna, etc |

| 6061 | Pipes, rods, profiles and plates for trucks, towers, ships, trams, furniture, mechanical parts, precision machining, etc | |

| 6063 | Building profiles, irrigation pipes and extruded materials for vehicles, stands, furniture, fences, etc | |

|

7000 series |

7075 | It is used for manufacturing aircraft structure and other high stress structural parts and molds with high strength and strong corrosion resistance |

| 7175 | High strength structure for forging aircraft. | |

| 7475 | Aluminum clad and non aluminum clad plates for fuselage, wing frame, stringer, etc. Other parts with high strength and high fracture toughness | |

|

8000 series |

8011 | The aluminum plate with bottle cap as the main function is also used in radiators, most of which are used in aluminum foil products |

|

For other materials, you can consult customer service |

||