Products

-

1060 Aluminum Alloy Manufacturer

1060 aluminum coil belongs to 1000 series aluminum coil, 1060 aluminum alloy is aluminum content (mass fraction) of 99.60%, not heat treatment to strengthen. Pure aluminum surface is silvery white, its density decreases with increasing purity or temperature. 1060 aluminum production process is relatively simple, relatively mature technology, the price relative to other high-grade aluminum alloy to be much cheaper.

-

6061 Aluminum Alloy Manufacturer

6061 aluminum alloy after heat treatment the pre-tension technology production of high quality aluminum alloy products, its strength is not compared with 2 or 7 XXX XXX department system, but its more magnesium, silicon alloy properties, has the excellent processing performance, excellent welding characteristics and electroplating, good corrosion resistance, high toughness and processing after deformation, dense material without defects and easy polishing, coloring film easily, good features such as oxidation excellent results.

-

5083 Aluminum Alloy Manufacturer

5083 aluminum coil is a high magnesium alloy with traces of manganese and chromium is known for exceptional performance in extreme environments. 5083 aluminum coil is highly resistant to attack by both seawater and Industrial chemical environments.

Aluminium alloy 5083 contains 5.2% magnesium, 0.1% manganese and 0.1% chromium. In the tempered condition, it is strong, and retains good formability due to excellent ductility. 5083 has high resistance to corrosion, and is used in marine applications. It has the low density and excellent thermal conductivity common to all aluminium alloys.

-

China Manufacture Supplier 1100 Aluminum Coil

1100 aluminium coil is pure aluminium, with excellent forming characteristics. 1100 is a typical industrial pure aluminum (99.00% of aluminum), and cannot be heat treated. The Aluminum 1100 coils are sensitive to high temperatures ranging between 200 and 250°C, but the strength of the coils can be increased at subzero temperatures. CHAL will supply superior quality aluminum 1100 coil at, a reasonable price with ASTM-B-209M, BS EN 485-2, BS EN 573-3, GB/T3880-2008 standard guaranteed.

-

China Manufacture Supplier 1060 Aluminum Plate

Alloy 1060 is a relatively low strength, high purity alloy with a 99.6% minimum aluminum content. It is noted for its excellent welding characteristics and formability along with good corrosion resistance. It has excellent forming capability by cold or hot working with commercial techniques and may be welded by standard commercial methods.

The entire 1xxx alloy group displays excellent forming, welding, brazing and finishing characteristics, and can easily be impacted, cold drawn, deep drawn and bent into various configurations. The characteristics of alloy 1060 make it ideal for chemical and food handling equipment, as well as for food, pharmaceutical and liquid containers.

-

China Manufacture Supplier 2024 Aluminum Plate

Aluminum alloy 2024 is good low-temperature alloys. 2024 is primarily alloyed with copper. It also contains manganese and magnesium and can sometimes contain smaller amounts of silicon, iron, chromium, zinc and/or titanium.

Its main use is in applications that require high strength to weight ratio and good resistance to fatigue. It has the property to be welded but only through friction welding.Good machinability and surface finish capabilities. A high strength material of adequate workability.

-

China Manufacture Supplier 3003 Aluminum Plate

3003 aluminum sheet belongs to 3XXX aluminum sheet, both in terms of sales volume and user acceptance, which are currently a better product. 3003 aluminum plate is usually called an anti-rust aluminum plate.

3003 aluminum plate has manganese alloy elements, which is superior to conventional 1 series aluminum plate in anti-rust performance. At present, the most common applications of 3003 aluminum plates on the market are high-speed traffic signs, building signs, high-speed barriers, building shells, etc., which are all popular applications of 3003 aluminum plates.

-

China Manufacture Supplier 3004 Aluminum Plate

3004 aluminium alloy is an alloy in the wrought aluminium-manganese family (3000 or 3xxx series). It is similar to the 3003 alloy, except for the addition of approximately 1% magnesium.

It can be cold worked (but not, unlike some other types of aluminium alloys, heat treated) to produce tempers with a higher strength but a lower ductility. Like most other aluminium-manganese alloys, 3003 is a general-purpose alloy with moderate strength, good workability, and good corrosion resistance. It is commonly rolled and extruded, but typically not forged. As a wrought alloy, it is not used in casting

-

China Manufacture Supplier 3105 Aluminum Plate

Aluminum alloy 3105 is essentially a 98% aluminum alloy with minor additions to increase strength over that of alloy 1100 and 3003. It is not hardenable by heat treatment and it has good corrosion resistance, formability and weldability.

3105 aluminum alloy has good corrosion resistance, good plasticity and processability, and the performance of gas welding and arc welding is good. 3105 aluminum has slightly higher strength than 3003 aluminum, others properties are similar to 3003 aluminum alloy.

-

China Manufacture Supplier 5052 Aluminum Plate

The 5052 aluminum plate is an alloy that has been formed with a combination of metals, which include 0.25 percent chromium and 2.5 percent magnesium. It has great workability and is readily machinable and weldable. Its high fatigue strength and medium static strength, plus excellent corrosion resistance, make it popular for use in marine atmospheres. Like with other aluminum alloys, this grade of aluminum has excellent thermal conductivity. In order to harden this alloy, cold working should be used, since heat working can’t achieve this. It has excellent endurance limits and fatigue properties.

-

China Manufacture Supplier 6061 Aluminum Plate

6061 Aluminum plate (AMS 4027) is one of the most versatile grades of high strength, heat treatable aluminum alloys. The T6 temper is achieved through a solution heat treatment and artificial aging to achieve the greatest level of precipitation hardening, and it resists stress cracking due to the inclusion of magnesium and silicon as major alloying elements. It is used for engineering and structural applications, boats, furniture, stairs, and more.

-

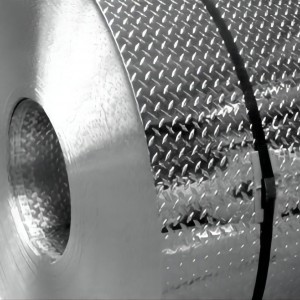

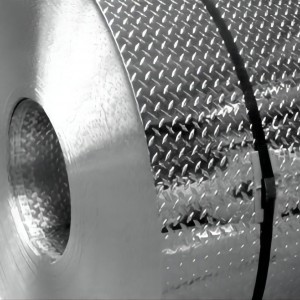

China Manufacture Supplier Aluminum Coil

Aluminium Plate is highly resistant to corrosion, very ductile and has a reflective finish. It is roughly 1/3 the weight of mild steel, so that it is ideal for general sheet metal work where moderate strength is required but weight is an issue. Aluminium plate is straightforward to form or bend using hand tools or a bending brake. It also can be cut using a jigsaw with the correct blade, on a guillotine. Aluminium plate can be used for a wide range of applications from tooling plate, structural, general engineering, transport, agricultural, architectural, truck bodies, trailer parts ship and boat building.